3.1 Part of regulations, laws and standards regarding SF6 in China

(1) GB 13690 “Classification and Labeling of Commonly Used Hazardous Chemicals” classifies SF6 as “A2.2 non-combustible gas (including combustion-supporting gas)” in the category of “A2 compressed gas and liquefied gas”.

(2) The State Council Order of the People’s Republic of China “Regulations on the Safety Management of Hazardous Chemicals”; the Ministry of Labor [1996] No. 423 “Regulations on the Safe Use of Chemicals in Workplaces” and other regulations issuing corresponding regulations on the safe use, production, storage, transportation, loading and unloading of hazardous chemicals.

(3) TSG_R0006-2014 “Gas Cylinder Safety Technical Supervision Regulations” in “7.4.1 Inspection Cycle of Various Gas Cylinders” stipulates that gas cylinders containing nitrogen, sulfur hexafluoride, inert gas, and non-corrosive with a purity of 99.999% or more shall be inspected every 5 years; gas cylinders containing corrosive effects on the material of the cylinder, diving cylinders and gas cylinders that are often in contact with seawater shall be inspected every 2 years; The gas cylinders are inspected every 3 years. For the gas cylinder of the previous model containing mixed gas, the inspection period shall be determined according to the gas with the shortest inspection period in the mixed gas. “

(4) “3.2.1 Classification” in GB 26571-2011 “Specification for Storage Period of Special Gases” classifies sulfur hexafluoride as “non-reactive gas”, and its storage period is in accordance with the requirements in “Table 2 Storage Period” of the standard. It should be less than 36 months.

(5) GB 12022-2014 “Industrial Sulfur Hexafluoride” makes relevant regulations on the quality and testing methods of new sulfur hexafluoride gas. Among them, the quality of sulfur hexafluoride fresh gas is compared with the quality of international IEC standard New gas:

| Indicator name | GB12022 | IEC60376 | ||

|---|---|---|---|---|

| Invalid till 2006 | Current from 2014 | Invalid till 1971 | Current from 2005 | |

| Carbon tetrafluoride (CF4) | ≤0.04% | *≤100*10-6 | ≤0.05% | ≤0.2% |

| Hexafluoroethane (C2F6) | — | *≤200*10-6 | —- | —- |

| Octafluoropropane (C3F8) | —- | *≤50*10-6 | —– | —– |

| Air (N2+O2) | ≤0.04% | *≤300*10-6 | ≤0.05% | ≤0.24% |

| Moisture (H2O) | *≤5*10-6 (-49.7℃) | *≤5*10-6 | *≤15*10-6 | *≤25*10-6 (-36℃) |

| Acidity (in HF) | *≤0.2*10-6 | *≤0.2*10-6 | *≤0.3*10-6 | *≤1*10-6 |

| Hydrolyzable fluoride (in HF) | *≤1.0*10-6 | *≤1.0*10-6 | *≤1.0*10-6 | —- |

| Mineral Oil | *≤4*10-6 | *≤4*10-6 | *≤10*10-6 | *≤10*10-6 |

| SF6 Purity | ≥99.9% | ≥99.9% | ≥99.8% | ≥99.7% (tested in liquid) |

| Toxicity test | Non-toxic | Non-toxic | Non-toxic | Non-toxic |

| Note: 1. “*” is the quality score According to the comparison of the above national standards and international standards on sulfur hexafluoride new gas parameters, it can be seen that the national standards currently used in China are far more strict than international standards. | ||||

- GB8905-2012 “Guidelines for Gas Management and Detection in SF6 Electrical Equipment”

- DLT595-2016 In “Guidelines for Gas Supervision of SF6 Electrical Equipment”, “4 The Supervision and Management for new SF6 gas” requires the storage of SF6 cylinders should be “store upright in a cool, dry and ventilated special place.”; requires the test time of SF6 gas in the SF6 gas cylinder should be “If the SF6 gas has been stored in the cylinder for more than half a year, the humidity and air content should be rechecked before refill to SF6 chamber, the results should meet GB/T12022 standard.”- “7 the recovery and purification of SF6 Gas” , “the purified gas shall meet the requirement in GB/T 12022 Standard”.

- National Energy Security 2014 No. 161 “the twenty-five key requirements for preventing electrical production accidents” “7.3 strictly execute the regular inspection system for pressure vessel” make requirements for the management of pressure vessel; “13 preventing GIS, switch accidents” make a detailed statement for the use of requirements and precautions for SF6 gas in electrical equipment.

- The six items of “Appendix B the impact of SF6 gas on environment” in GBT 28534-2012 “the impact of the release of SF6 gas in high-voltage switch and control equipment on environment and health” “B.6 the Environmental Compatibility Policy of SF6 gas” makes a description as below: “ The SF6 gas shall be proceeded in a closed-loop, to avoid any unintentional release to environment. Among all the proposes, the gas recovery and reuse has the highest priority. The goal of the voluntary agreements signed by design manufacturers and users in some countries is to reduce the release of SF6 gas in electrical equipment. In general, in this agreement, the environment compatibility policy refers to the opening, manufacturing, installation, operation, maintenance and end-of-life treatment in the SF6 electrical equipment, and the use of advanced technology and procedure make the minimal release of SF6 emission.

- Ministry of Environmental Protection HJ2025-2012 “Technical Specification for the collection, storage, and transportation of hazardous wastes” makes relevant specification and requirement for the collection, storage, and transportation of hazardous wastes. For example, if SF6 gas is not treated accordingly, it is also classified as hazardous wastes, and the collection, storage, and transportation will be subject to strict requirements and controls.

- DLT 1050-2016 “Technical Guidelines for Electrical Environmental Protection” “5.2.4.6 the following supervision should be carried out for SF6 gas” article requires:

- When the SF6 equipment is overhauled or disassembled, the removed adsorbent, metal powder and other wastes should be disposed in accordance with DL/T 639

- When the SF6 equipment is detected or retired, the SF6 gas shall be recovered and reused to prevent SF6 emission during recovery process. The recovery rate of SF6 gas shall reach 100%, and random discharge is strictly prohibited.

- The regenerated qualified SF6 gas should be used firstly when recharging SF6 gas.

- DLT 1553-2016 “Working Regulation for SF6 purification and treatment” make corresponding requirement and specification for relevant work regulations of SF6 purification and reuse.

- DLT 662-2009’s “Technical Condition of SF6 gas recovery equipment” make corresponding requirement and specification for SF6 recovery equipment.

- State Grid Corporation’s “Measurement of Supervision and Administration for recovery, treatment and recycling of SF6 gas by State Grid Corporation” stipulated in the “Chapter One General Provisions Article 2”, that the work of recycling SF6 insists on the principle of “decentralized recovery, centralized treatment, unified testing and recycling.”. It is included in the company’s daily production operation and maintenance management.

3.2 The management for SF6 gas

According to the relevant regulations and standards about SF6 cited in chapter 3.1 of this article, we can see that our country has not only monitored and supervised the entire life cycle of SF6 gas, but with the improvement of government and civil awareness for environmental protection, the supervision policy for greenhouse gases such as SF6 will also be more and more strict. For example, State Grid Corporation’s “2006 Social Responsibility Report” published in 2007 promised to “reduce pollutants and wastes emission, recycle and reuse SF6 gas” energy saving and emission reduction measurement, and promote SF6 recycle and reuse pilot working in four provinces. Before this, Guangdong Power Grid company, a subsidiary of Southern Power Grid, had already proposed to recover SF6 gas in 2005.

As time goes on, in recent years, the management of SF6 gas has been included in the environmental performance evaluation content, whether in government evaluation or within the power grid system.

Among them,“Measures for the Supervision and Administration of the Recovery, Treatment, and Recycling of SF6 gas by State Grid Corporation in China,” issued by State Grid Corporation in 2017, make the following requirements for the management of SF6 gas:

Article 20, Indicators and contents of inspection and evaluation

- The recovery rate in the overhauled and decommissioned equipment shall not be less than 95%.

- The purification treatment rate of SF6 gas shall not be less than 98%.

- SF6 recycling account (see annex 3)

- The relevant management system, equipment assets account, gas quality control record for SF6 gas.

- Timeliness and completeness of SF6 gas information data statistics.

- Implementation and executive condition of relevant funds.

Article 21, the Evaluation Results

- The evaluation results of SF6 recycling and reuse is included in the annual environmental performance management and evaluation system in every province.

- According to actual work, each provincial company can establish a reward and punishment mechanism of SF6 gas, and report to the company for record.

3.3 Economic Benefits of SF 6 gas recovery and recycling

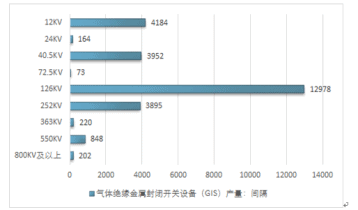

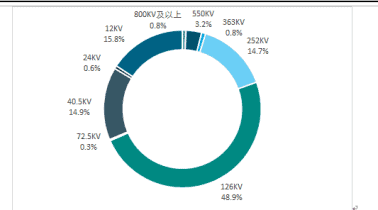

With our country’s continuous development of high-voltage electrical technology in recent years, we have established and operated a million-grade high-voltage grid system. This technology filled the international gap and made our high-voltage power grid technology the world’s leading level. As of the end of 2008, the UHV that has been put into operation by State Grid Corporation of China has reached “80 AC and 10 DC”, with a cumulative power transmission exceeding 1.24 trillion KWh. At the same time, because of the continuous increase in electricity consumption in China, we have set off a construction boom to increase the power system’s capacity. Every year, large quantities of GIS, GIT, GIL, and GCB used SF6 as insulation, and an arc extinguishing medium was put into use and operation. According to the statistics, the total output of gas-insulated metal-enclosed switchgear (GIS) in our country in 2016 was 26516 intervals.

In 2016, the output of 40.5kV gas-insulated metal-enclosed switch gear (C-GIS) was 3952 intervals, an increase of 1458 intervals over the previous year, a growth rate of 58.46%. There were 12 manufacturing enterprises, an increase of 2 over the previous year. The company with the highest output is Schneider Switch (Suzhou) Co., Ltd. (output 1583 intervals), which accounts for 40.05% of the industry’s total production.

In 2016, the output of 12kV gas-insulated metal-enclosed switch gear (C-GIS) was 4184 intervals, an increase of 1734 intervals over the previous year, a growth rate of 70.78%. There were 9 manufacturer enterprises, an increase of 3 over the previous year. The company with the highest output is Hangzhou Xinmei Complete Electrical Appliance Manufacturing Co., Ltd.

Because of the continuous increase in electricity consumption in China, we have set off a construction boom to increase the power system’s capacity.

Along with electrical equipment’s establishment and operation with large quantities of SF6 gas as insulation and arc extinguishing medium, our country’s consumption of SF6 in my country’s power industry is also increasing yearly.

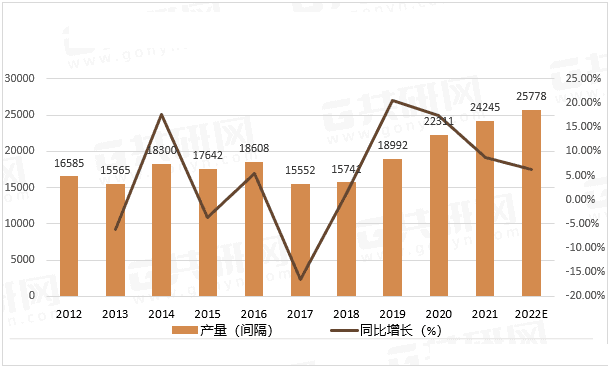

The consumption of sulfur hexafluoride in my country’s power industry is also increasing yearly. According to incomplete statistics, the current use of SF6 in the power industry in our country is about 4000-5000 tons. Major domestic SF6 manufacturers, such as Liming Chemical, China Nuclear Honghua, Yingde, Kemet, etc., have recently expanded their production capacity. At the same time, many SF6 manufacturers with smaller production capacities have been established. The production volume of SF6 gas in China has increased, but the supply price of SF6 gas has fallen relatively. However, with the guidance of national policies and increased social attention, the recycling of SF6 gas is the main direction of the future use of SF6 gas.